LEVELS OF SYSTEM INTEGRATION IN DIGITAL TWINS: PROS, CONS AND CRITICALITIES

Three levels of progressive IT integration for Digital twins: Standalone Models, Digital Shadows, and Digital Twins

In the realm of modern technology, digital twins have become essential tools for predicting outcomes, optimizing systems, and managing complex processes. As industries increasingly rely on digital representations of physical entities, understanding the different types of simulation models by technology readiness —standalone simulations, digital shadows, and digital twins—is crucial. Each of these models serves a unique purpose and comes with its own set of advantages and disadvantages. This article will explain what each model is, and explore the pros and cons associated with them.

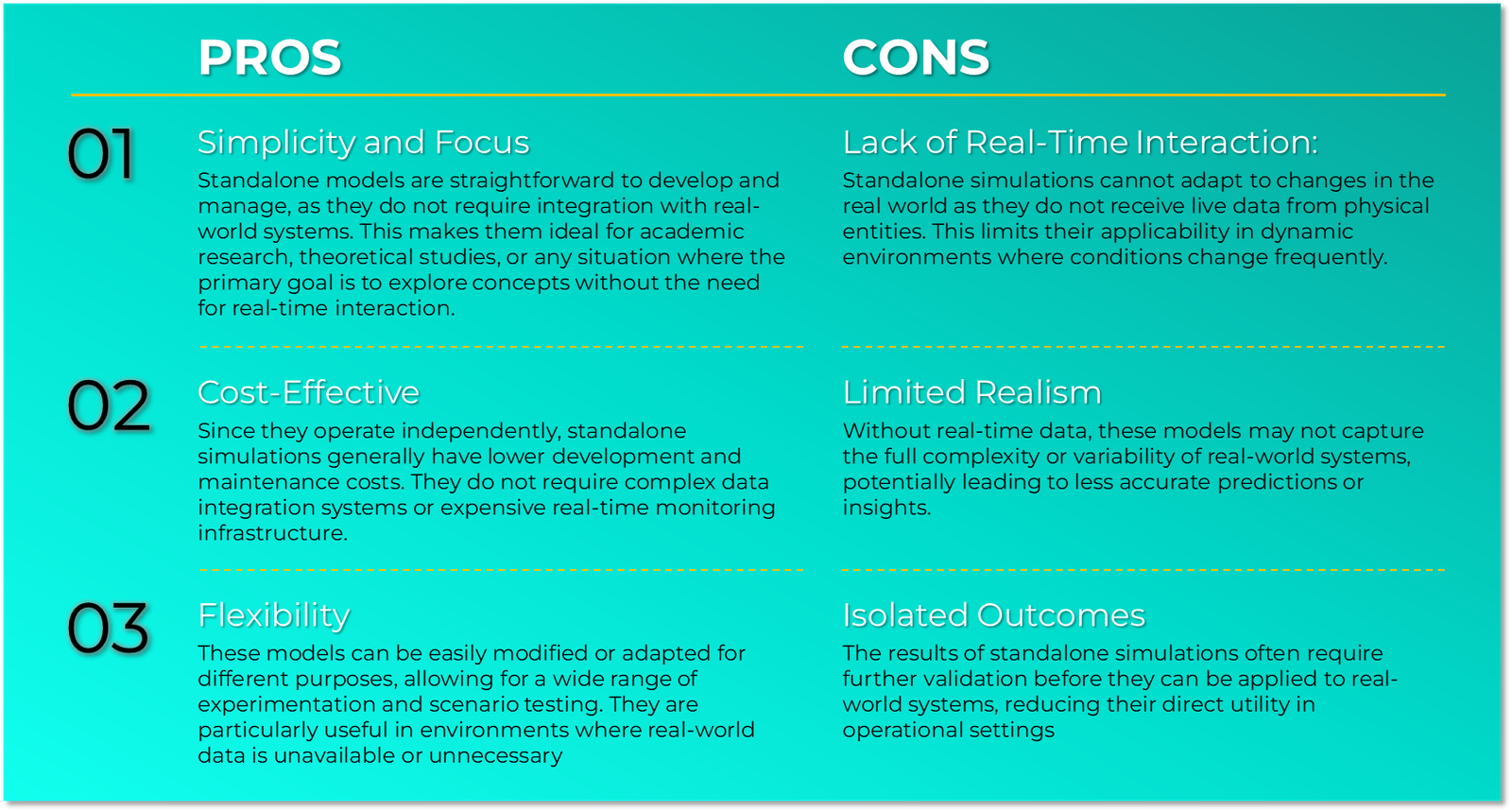

1. Standalone Digital twins

Standalone digital twins are self-contained virtual models that operate independently of any physical system. These models do not interact with real-world entities in real-time and are typically used for theoretical analysis, scenario testing, and educational purposes. The simulation is driven by predefined parameters, defined algorithms and behaviors, and initial conditions, without any live data input from the physical world.

Best suited for theoretical exploration and what-if scenario testing, where real-time interaction with physical systems is not required, such twins typically support in investment optimization, optimal policies definition, risk management and mitigation action testing, operational improvements opportunities identification both from an efficiency and efficacy point of view.

As what-if scenarios are strictly performed in a virtual model, this type of digital twin is particularly useful for supporting critical decision making processes by creating and comparing many alternatives in a risk-free environment.

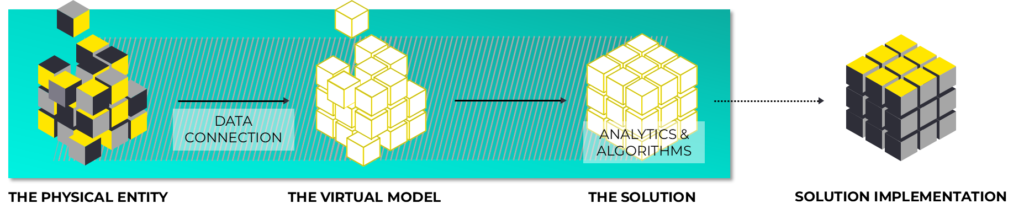

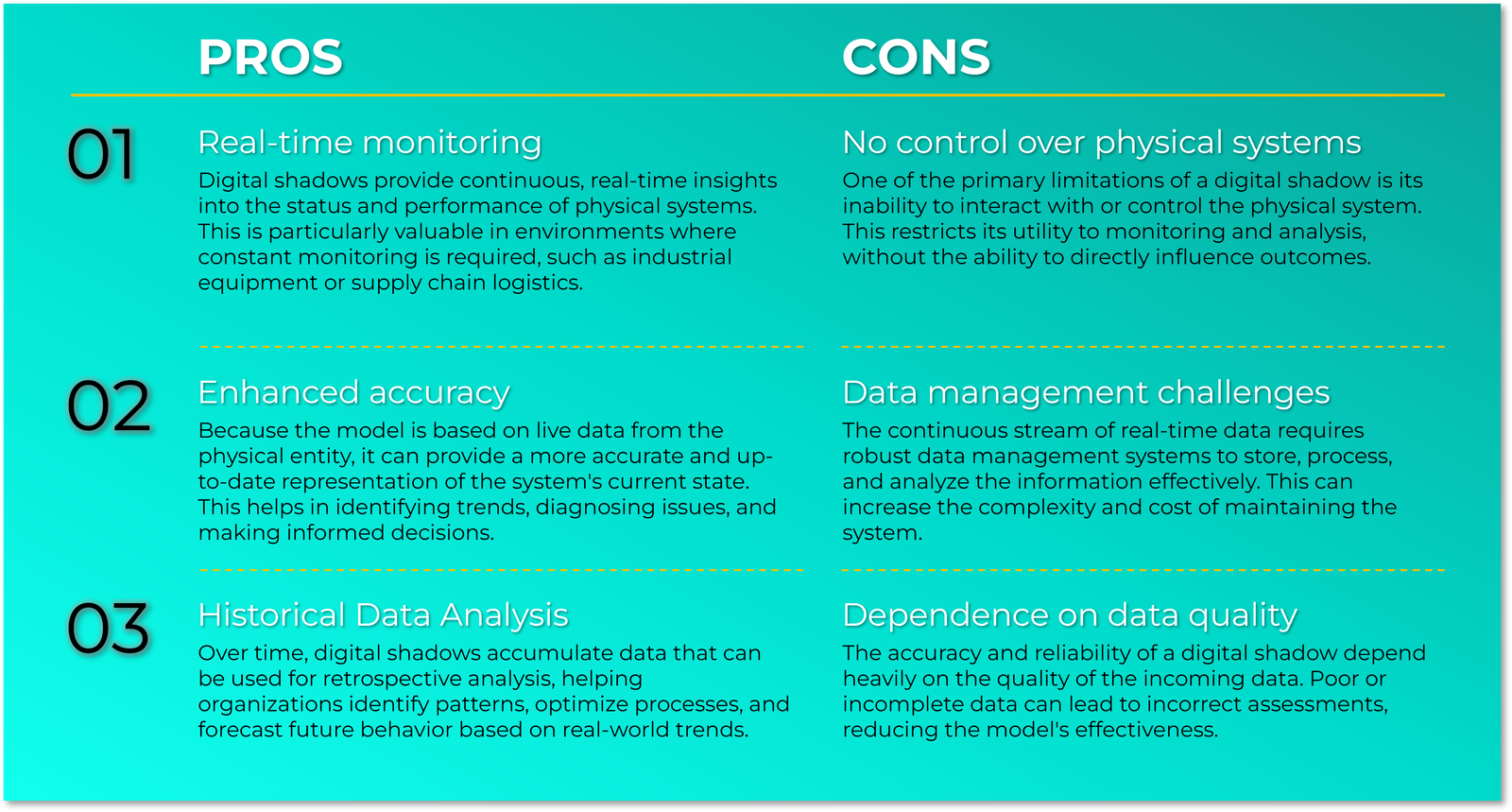

2. Digital Shadows

A digital shadow is a virtual model that mirrors the state of a physical entity through a one-way flow of data. The physical system sends data to the virtual model, which then uses this data to reflect the current state of the system. Unlike a digital twin, a digital shadow does not interact with or influence the physical system—it purely monitors and analyzes it.

If structured only for monitoring purposes, a twin allow to have a single point of access to the status of the physical asset to detect any problem/opportunity and increase the span of control.

However, digital shadows could also have forecasting capabilities in the form of predictive analytics or simulative algorithms. For example, a predictive model could forecast the remaining useful life of an equipment based on vibration, thermography patterns and past failures to tell when such equipment require maintenance and the likelyhood of each component to be the root cause of the failure. On the other hand, simulative approaches trascend the data correlation – which could be biased, for example, by any event or variable not considered in the model – and rather create predictions based on interactions of smaller virtual entities, characterized by a certain behavior, which are part of the broader physical environment replicated. An example of simulative digital shadow could be to predict the throughput of a factory based on the actual inventory, work in progress and available resources (equipment, people).

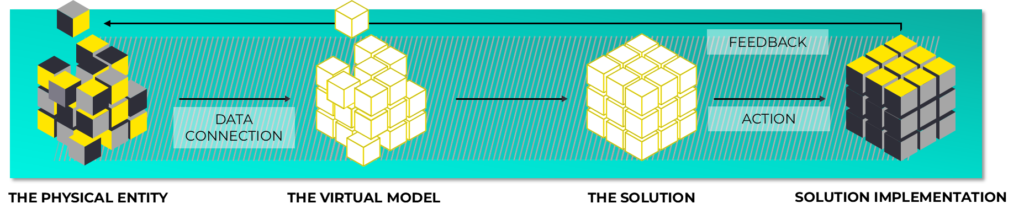

3. Digital twin

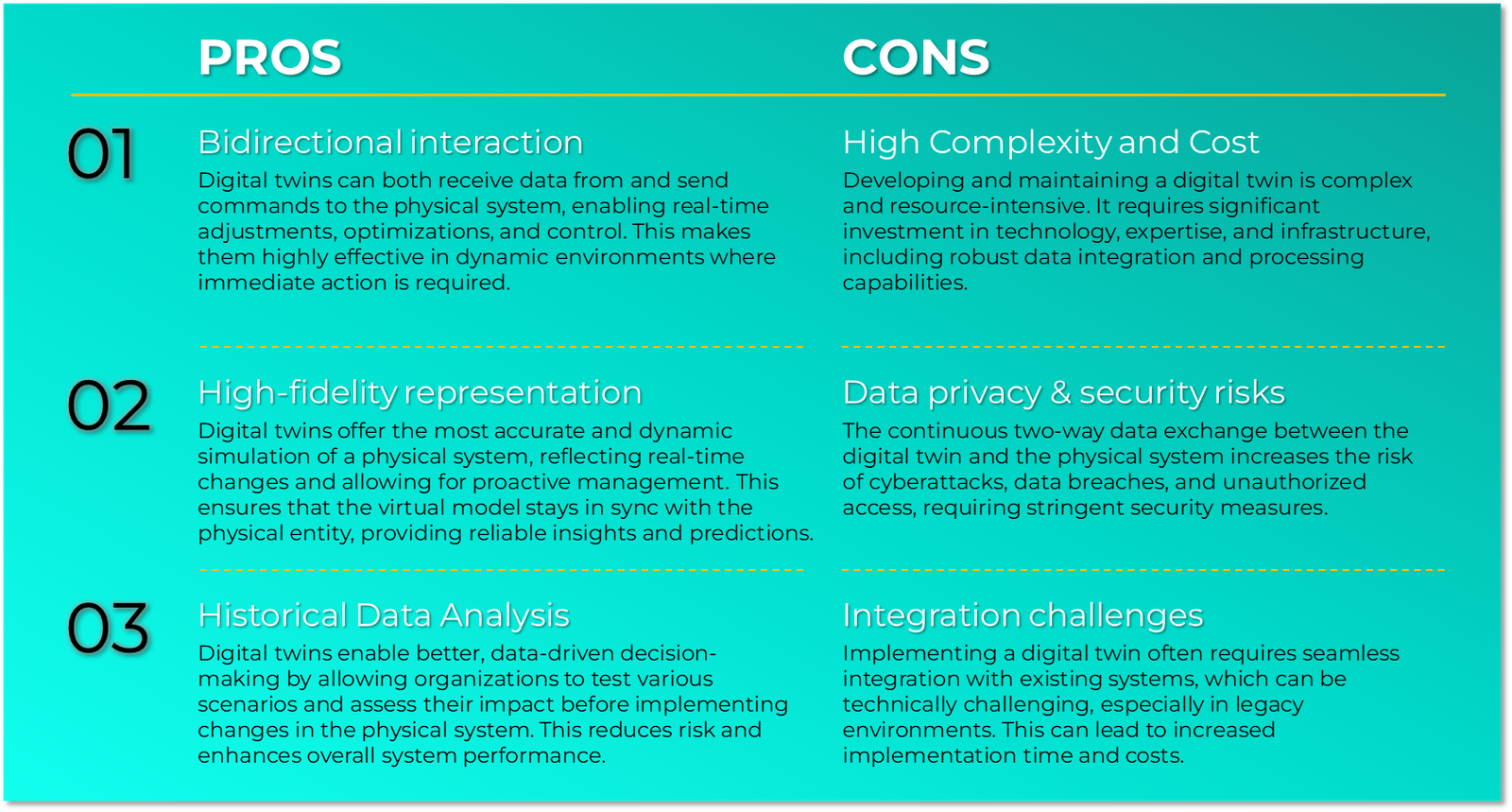

A digital twin is a sophisticated virtual model that not only reflects the current state of a physical entity but also interacts with it through two-way data flow. This means that the digital twin can send commands and adjustments back to the physical system, allowing for real-time optimization, control, and intervention. Digital twins are widely used in industries where precise control and real-time decision-making are critical.

As for the digital shadow, the digital twin could leverage simulations or predictive analytics, or even both, but it is able to apply actions. For example, a digital twin for advanced control at machine level, typically leveraging predictive analytics, could self-balance parameters of an oven based on the current and future content or open a valve to mantain a certain level of water quality. On the other hand, by using a simulative approach – for example – in the context of energy management, a digital twin could actively support in managing an energy accumulator by analyzing real-time data on energy demand and future weather forecasts. The digital twin predicts different oucomes based on different accumulation policies, energy demand, energy costs and weather forecast, thereby providing all the informations to make informed decisions to optimize energy usage to reduce reliance on non-renewable sources. Once explored all the what-if scenarios, the digital twin detects the best policy and dispatches it for execution.

Finally, a digital twin could rely on both simulations, predictive analytics and machine learning for seamless automatic optimization.

For instance, in prescriptive maintenance, a digital twin of a manufacturing robot could continuously monitor its performance, using machine learning to detect patterns that indicate wear or potential failures, such as abnormal vibrations or temperature spikes. The digital twin could also run simulations to assess the impact of different maintenance strategies. If the machine learning model predicts that a critical component is likely to fail soon, the digital twin could simulate various scenarios, such as replacing the part immediately, delaying maintenance, or adjusting operating conditions to extend the component’s life.

Based on these simulations and predictions, the digital twin could then prescribe the optimal maintenance action—such as scheduling a replacement during the next production downtime to avoid costly unscheduled outages. Additionally, it could adjust the robot’s operating parameters in real-time to minimize wear until the maintenance is performed, ensuring continuous operation while preventing catastrophic failures. This approach not only enhances machine reliability but also optimizes maintenance schedules, reducing costs and downtime

01

DIGITAL TWIN TYPES AND CHARACTERISTICS

In-Depth exploration of Digital Twin Types: characteristics, technologies, and value added by area of application

02

DIGITAL TWIN ABSTRACTION LEVEL

Understand what is the abstraction level – from broad E2E digital twins to detailed object level digital twin – inputs, outputs and key questions answered

03

dIGITAL TWIN AND SYSTEM INTEGRATION

From standalone simulations to closed-loop interaction with corporate IT systems: pros, cons and challenges from proof of concept to enterprise scalability

04

dIGITAL TWIN STANDARDS

Standard vs. Custom Digital Twins: Navigating Complexity in Modern Systems