Measuring Supply Chain Carbon Footprint

When assessing the supply chain sustainability, various key performance indicators (KPIs) must be considered. The most commonly used is the supply chain carbon footprint estimation, which serves as a major proxy for environmental sustainability.

Carbon footprint refers to the total greenhouse gas (GHG) emissions, measured in CO2 equivalent, generated directly or indirectly by an activity, company, product, or service.

Importance of Supply Chain Carbon Footprint

The supply chain carbon footprint serves as a key proxy for environmental sustainability and is increasingly used in regulations such as the European Green Deal, the Paris Agreement, and the EU’s Net-Zero Industry Act. These initiatives highlight its role as a target for reducing emissions.

Its prominence stems from the ability to summarize all sources of GHG emissions within a company’s supply chain, offering a clear metric for evaluating its impact on climate change.

Given the importance of carbon footprint indicator, it is necessary to focus on its computation to comprehend how it could be embedded in a sustainable supply chain simulation model.

Calculating Supply Chain Carbon Footprint

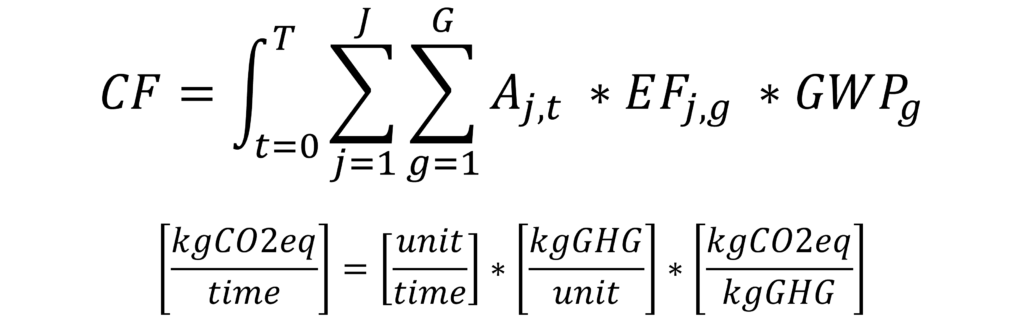

The calculation of carbon footprint involves three main inputs:

- Activity Volume (A): Measures the quantity of activity that produces emissions (e.g., in kg, liters, kWh, etc.).

- Emission Factor (EF): A coefficient defining how much GHG is released per unit of activity.

- Global Warming Potential (GWP): A conversion factor that expresses GHG emissions in CO2 equivalent.

The operators at the start of the formula are interpreted as follows:

- Integral over time (t): Emissions are calculated across the entire defined time period.

- Summation over activities (j): All activities generating emissions are included in the carbon footprint calculation.

- Summation over GHG gases (g): All greenhouse gases generated or used in the activities are considered, with their effects converted to CO2 equivalents using the GWP coefficient.

Represents the quantity of the flows associated to a certain activity (j) in the time period considered (t). Depending on the nature of the activity considered, this variable may assume differents measurment unit: kg, ton, liters, m3, MJ, kWh, km,…

Choosing the right level of detail for activity mapping affects data collection, estimation accuracy, and the ability to target emission-reduction efforts. Detailed mapping yields precise results but requires extensive data, while a high-level approach may lead to less accurate estimates.

An emission factor (EF) represents the amount of a pollutant released relative to the activity causing the emission. These factors are usually expressed as the pollutant’s weight per unit of activity and help estimate emissions from various pollution sources.

The coefficient is related to a specific activity (j) that defines the quantity of emissions for a particular GHG (g) per unit processed by that activity (volume/mass/distance/energy, etc.).

They are typically averages of available quality data and assumed to be representative over the long term.

The Global Warming Potential (GWP) factor allows for comparison between different GHGs by converting their emissions into CO2 equivalent.

It is a conversion factor to CO2 equivalent mass relative to the global warming potential of a specific greenhouse gas (g).

The GWP coefficient is purely scientific and does not vary by application. Typically, the 100-year GWP is used. In carbon footprint calculations, the GWP factor is sourced from scientific references.

Carbon Footprint according to the GHG Protocol

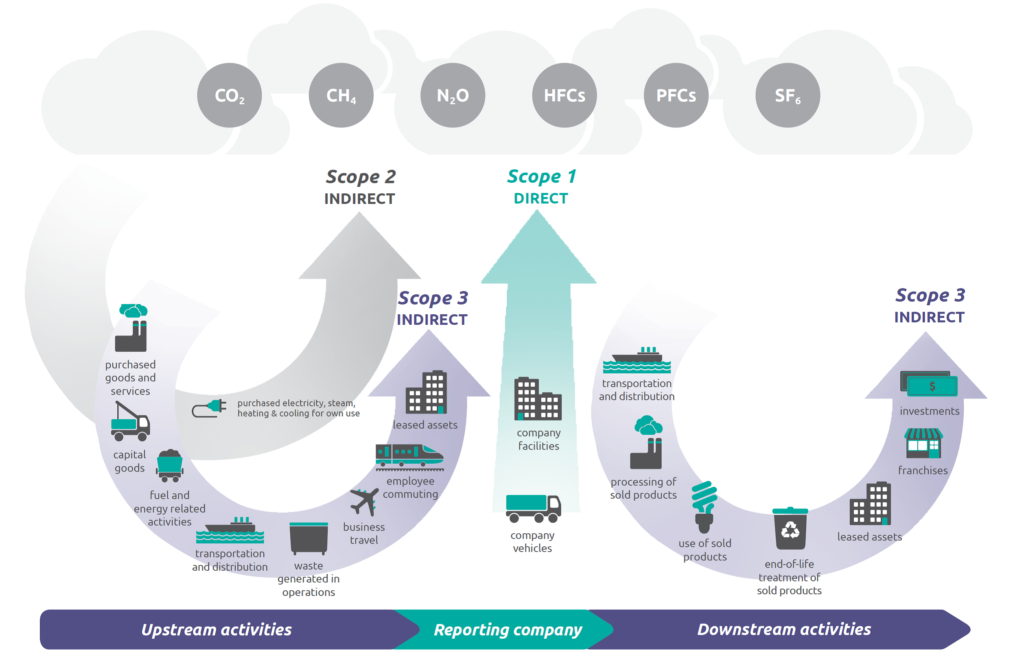

The GHG Protocol is the primary framework for calculating a supply chain carbon footprint.

It defines emissions in three scopes:

- Scope 1: Direct emissions from owned or controlled sources (e.g., fuel, chemicals, and factory emissions).

- Scope 2: Indirect emissions from purchased energy like electricity, heat, and steam.

- Scope 3: Indirect emissions across the value chain, both upstream and downstream. This scope often accounts for the largest share of emissions and has become mandatory under the EU’s Corporate Sustainability Reporting Directive (CSRD).

By integrating carbon footprint estimation into supply chain models, companies can monitor, optimize, and reduce their environmental impact, contributing to global sustainability efforts.

01

Modeling Sustainable supply chain

Sustainable development modeling approaches and strategies.

02

Supply chain carbon footprint

How to measure one of the most important indicators for sustainability.

04

Skills and technologies

Learn about the skills and technologies involved in this cutting-edge technology

06

Applying Simulation to the S&OP process

MRP, Scheduling, and in between Simulation Modelling: discover how