Digital twin entities: a matter of size and level of abstraction

What is a physical entity?

As explored in the previous article of the digital twin collection, digital twins are fundamentally based on the replication of a physical entity within a virtual environment. By creating a digital counterpart of this entity, organizations can simulate, monitor, and optimize performance in ways that would be difficult, impossible or very expensive with the physical entity alone.

The term “entity” is intentionally broad as it can refer to virtually anything in the physical world. The physical entity could be as small as a single component within a machine or as large as an entire city or even a global supply chain network. This flexibility is one of the defining characteristics that make digital twins so powerful and versatile across various industries.

While the clustering of digital twins based on their scope and type presented in the previous article is a good excercise that allow to appreciate the variety and vastness of the digital twin realm, it is time to delve into the nature of physical entity.

Why Does the Physical Entity Matter?

The nature of the physical entity being replicated significantly influences the complexity, inputs, outputs, and key questions that a digital twin are able to address. Different entities require different types of data to create an accurate and functional digital twin. Additionally, the insights generated by the digital twin, as well as the questions it can answer, will vary depending on what is being replicated.

For instance:

A digital twin of a single machine component (like a turbine blade) may require input data such as material properties, stress conditions, and operational temperatures. The digital twin could answer questions like: “How will this component perform under extreme conditions?” or “What is the expected lifespan of this component?”

A digital twin of an entire production line requires a broader set of input data, including the configuration of machines, process timings, and workflow logistics. It might answer questions such as: “Where are the bottlenecks in production?” or “How can we optimize the line to reduce waste and increase throughput?”

A digital twin of a city involves even more complexity, pulling in data from traffic patterns, energy consumption, weather conditions, and public infrastructure. This kind of digital twin could provide insights into questions like: “How can we reduce traffic congestion in peak hours?” or “What are the most effective ways to reduce the city’s carbon footprint?”

Each type of digital twin is tailored to the specific needs of the entity it replicates, and the scale of the entity plays a crucial role in determining what data is needed and what questions can be addressed. Moreover, as we will see through examples for each digital twin type, the larger and more complex the entity, the more data points are involved, and the more sophisticated the digital twin must be to provide useful insights.

Examples of Physical Entities and Their Digital Twins

Let’s break down the types of physical entities typically replicated by digital twins, organized by scope and scale—from the smallest to the largest. We’ll explore the types of input data required, the outputs generated, and the key questions that these digital twins are designed to answer.

1. Product digital twins

A single part or subassembly of a product, such as a turbine blade, an engine valve, or a circuit board. A digital twin of a component might be used to analyze stress, wear, or efficiency under various conditions.

Key Questions answered by a digital twin: How does this component behave under different loads? What is the expected lifespan? How can we optimize the design for better performance?

A complete manufactured item, like a car, jet engine, or smartphone. The digital twin of a product allows for the simulation of the entire product's lifecycle, from design and manufacturing to operation and maintenance.

Key Questions answered by a digital twin: How can we improve the product's performance? What are the potential failure points? How does the product interact with other systems?

Product System: A complex assembly composed of multiple interconnected products, such as an aircraft or an automobile powertrain. This type of digital twin manages the interactions between various components and subsystems.

Key Questions answered by a digital twin: How do the subsystems interact under different operational scenarios? What are the impacts of component failures on the overall system? How can we optimize the system for better efficiency?

2. Process digital twins

- A single machine or station within a production line, such as a CNC machine or a robotic arm. The digital twin of a workstation might be used to optimize machine performance or reduce downtime.

- Key Questions answered by a digital twin: How can we reduce cycle time? What is causing machine downtime? How can we increase throughput without sacrificing quality?

- An individual operation within a larger manufacturing process, like assembly, welding, or painting. Digital twins at this level help in refining specific steps to improve overall process efficiency.

- Key Questions answered by a digital twin: How can we improve the efficiency of this step? What is the impact of changing a process parameter? How does this step contribute to the final product quality?

- A sequence of workstations that work together to produce a finished product, such as a car assembly line. The digital twin of a production line provides a holistic view of how all the steps work together.

- Key Questions answered by a digital twin: How can we optimize the flow of products? Where are the bottlenecks? How can we improve line balance and reduce waste?

An entire facility that includes multiple production lines and processes. The digital twin of a manufacturing site helps in managing the complex interactions between different lines and processes.

Key Questions answered by a digital twin: How can we improve plant-wide efficiency? What is the impact of a line shutdown on overall production? How can we reduce energy consumption and waste?

Facilities where products are stored and distributed, such as Amazon fulfillment centers. Digital twins here focus on optimizing storage, retrieval, and distribution processes.

Key Questions answered by a digital twin: How can we increase picking efficiency? What is the optimal layout for storage? How can we reduce order fulfillment times?

The logistics and material flow within a single organization, spanning across various production lines and facilities. This type of digital twin is essential for optimizing internal logistics.

Key Questions answered by a digital twin: How can we optimize inventory levels? What is the most efficient way to route materials within the facility? How can we reduce lead times?

The broader supply chain that includes suppliers, manufacturers, and distributors. A digital twin of an external supply chain enables end-to-end visibility and optimization across the entire supply network.

Key Questions answered by a digital twin: How can we mitigate risks in the supply chain? Where are the vulnerabilities? How can we improve delivery times and reduce costs

3. Environmental digital twins

A single structure, such as a factory, office building, or hospital. The digital twin of a building might be used for energy management, safety monitoring, or space optimization.

Key Questions answered by a digital twin: How can we reduce energy consumption? What is the most efficient way to manage building operations? How can we improve safety and comfort for occupants?

A group of buildings within a confined area, like a university or corporate campus. This type of digital twin helps in managing resources and operations across multiple facilities.

Key Questions answered by a digital twin: How can we optimize energy usage across the campus? How can we improve transportation and logistics? How can we enhance security and emergency response?

A large area containing multiple manufacturing facilities and related infrastructure. The digital twin of an industrial park supports the coordination of activities across different facilities.

Key Questions answered by a digital twin: How can we optimize shared resources like power and water? How can we improve coordination between facilities? How can we reduce environmental impact?

- A section of a city, including buildings, roads, and infrastructure, such as a smart city district. Digital twins at this level are used for urban planning, traffic management, and public safety.

- Key Questions answered by a digital twin: How can we reduce traffic congestion? How can we improve public services? How can we enhance sustainability and reduce emissions?

- An entire urban environment, encompassing all infrastructure, transportation systems, and public services. A city-wide digital twin provides a comprehensive view of urban operations.

- Key Questions answered by a digital twin: How can we optimize city-wide resource management? How can we improve public safety and emergency response? How can we enhance the quality of life for residents?

- A broader area that includes multiple cities or a large geographic area, such as a metropolitan region. The digital twin of a region is essential for large-scale infrastructure management and regional planning.

- Key Questions answered by a digital twin: How can we manage resources across multiple cities? How can we improve transportation networks and reduce regional congestion? How can we enhance disaster preparedness and response?

An Entire Globe Digital Twin is the most comprehensive digital twin, replicating the entire Earth and all its systems—natural environments, human activities, and economic and social systems. It uses vast datasets, including climate, geospatial, biodiversity, and human activity data, to simulate and analyze global phenomena.

Key Questions Answered:

- Climate and Environment: What will the Earth's climate look like in the future? How can we mitigate and adapt to climate change? Which areas are critical for conservation?

- Sustainability and Resources: How can global resources be used sustainably? What are the global effects of local environmental changes? How can the global supply chain be optimized for sustainability?

- Global Risk and Disaster Management: How can we better predict and prepare for global natural disasters and pandemics? What are the global impacts of economic risks?

- Human Activity and Development: How do global human activities impact the environment? What are the long-term consequences of current development practices? How can sustainable development be promoted globally?

4. System digital twins

An Equipment Digital Twin focuses on replicating a specific piece of equipment, such as a CNC machine, turbine, or robotic arm, to optimize its operation through automatic calibration of its parameters. This twin uses real-time data from sensors embedded in the equipment to adjust settings for optimal performance.

Key Questions Answered by a digital twin:

- Operational Efficiency: How can the equipment’s parameters be automatically adjusted for maximum efficiency and minimal wear?

- Predictive Maintenance: When is the best time to perform maintenance to prevent unexpected breakdowns?

- Quality Control: How can the equipment be calibrated to ensure consistent quality in production?

- Energy Consumption: How can the equipment be optimized to reduce energy use without compromising performance?

- A group of interconnected machines or devices within a single system, such as a network of industrial robots. The digital twin of a machine system helps in optimizing the interaction and performance of multiple machines in a risk-free environment. Some simulative suits allow for machine programming and virtual commissioning in a risk-free testing environment before real world implementation

- Key Questions answered by a digital twin: How can we improve coordination between machines? What are the potential failure points in the system? How can we enhance overall system efficiency?

- A network of interconnected computers, servers, and devices, such as a data center or corporate IT network. This digital twin focuses on optimizing network performance, security, and resource allocation.

- Key Questions answered by a digital twin: How can we improve network reliability and uptime? What are the vulnerabilities in the system? How can we optimize resource usage and reduce costs?

A Global Macroeconomic Digital Twin simulates the entire global economy, encompassing international trade, financial markets, labor dynamics, and economic policies. This twin models economic indicators and trends to analyze and predict the impacts of various global economic factors.

Key Questions Answered by a digital twin:

- Economic Forecasting: How will global GDP, inflation, and employment rates change under different economic scenarios?

- Policy Impact Analysis: What are the potential effects of fiscal, monetary, and trade policies on global markets?

- Risk Management: How can we anticipate and mitigate the impacts of global financial crises or economic shocks?

- Trade and Supply Chain: How will changes in international trade agreements or tariffs affect global supply chains and economies?

5. Healthcare digital twins

- Represents individual cells, molecules, or biological structures, such as a digital model of a cancer cell or DNA strands. The digital twin at this level is used for detailed biological research and personalized medicine.

- Key Questions answered by a digital twin: How do specific treatments affect cellular behavior? What are the potential side effects of new drugs? How can we customize treatments based on individual cellular responses?

Represents specific tissue types within the body, such as muscle tissue or liver tissue. Digital twins of tissues are used to study the effects of diseases or treatments on particular parts of the body.

Key Questions answered by a digital twin: How does a disease progress within a specific tissue? What is the impact of a surgical procedure on the tissue? How can we optimize treatment strategies for tissue repair?

Represents a system of organs working together, such as the cardiovascular system or respiratory system. This digital twin is crucial for understanding complex interactions within the body.

Key Questions answered by a digital twin: How do different organs interact under stress? What is the impact of a disease on the entire system? How can we improve overall system health and function?

- Represents the entire body of an individual patient, encompassing all organs and systems. The digital twin of a patient is used for personalized medicine, predicting health outcomes, and optimizing treatment plans.

- Key Questions answered by a digital twin: How can we tailor treatments to an individual’s unique physiology? What are the potential side effects of a treatment? How can we improve patient outcomes?

Represents the entire body of an individual patient, encompassing all organs and systems. The digital twin of a patient is used for personalized medicine, predicting health outcomes, and optimizing treatment plans.

Key Questions answered by a digital twin: How can we tailor treatments to an individual’s unique physiology? What are the potential side effects of a treatment? How can we improve patient outcomes?

Represents larger groups or populations, used for public health analysis and epidemiology. This digital twin helps in managing and predicting health trends across populations.

Key Questions answered by a digital twin: How can we track the spread of diseases? What are the public health risks in a specific population? How can we improve public health strategies?

Impact of Entity Size on Digital Twins

While the combination of type of digital twin and its scope influence the technological stack, the scale of the physical entity being replicated directly influences the complexity, implementation timeline, and accuracy of a digital twin.

Smaller entities, like a single component or workstation, typically involve less complexity and are easier to simulate and optimize. They provide detailed insights that are critical for improving specific parts of a process or product. For example, a digital twin of a turbine blade might be used to test its durability under different operating conditions, providing valuable data that can improve design and manufacturing processes.

As the size of the entity increases, such as when dealing with a complete product system, production line, or entire supply chain, the complexity grows exponentially. This increase in complexity requires more advanced simulations, more sophisticated data integration, and more robust computational resources. For instance, a digital twin of a global supply chain must account for numerous variables, such as multiple products, different shipping types, stochastic lead times, transportation costs, and geopolitical risks, all of which interact in complex ways.

In monitoring digital twins, which track real-time data from physical entities, the complexity also translates into higher capital and operational expenditures. For example, monitoring a complex manufacturing site serving complex product mix involves tracking various machines, sensors, and processes, requiring substantial investments in IoT devices, PLCs, and data management systems.

In general, increasing the size of the digital twin – costs aside – is anyhow feasible when it comes to monitoring digital twins.

However, predictive, simulative, and prescriptive digital twins face further particular challenges as entity sizes increases.

These models rely heavily on accurate data and sophisticated algorithms to predict future outcomes or recommend optimal actions. As the entity becomes larger and more complex, the likelihood of encountering errors, double counting or misconfigurations increases.

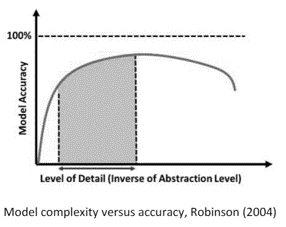

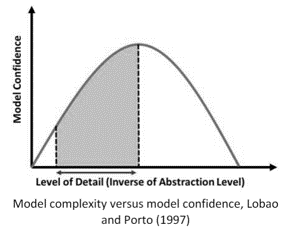

Large-scale predictive twins can be compromised by a single misconfigured constraint or an unclear variable, leading to unreliable outputs. In facts, while very low additional value is produced by inserting more and more variables into the model, the sheer number of variables increases the risk of:

- reaching local sub-optimal solutions

- to completely fail to find a solution

- adding white noise with redundant (i.e. two variables very similar and correlated to each other) and irrelevant variables, causing the model to fail in replicating the entity behavior

- Overcomplicating the model into a fuzzy, unclear representation of the physical entity

Additionally, the “black box” nature of many predictive models can make it difficult for users to trust the outputs, especially when numerous variables are involved.

On the other hand, simulative digital twins are affected by different criticalities. As simulative digital twins attempt to mimic real-world behavior by breaking down complex systems into smaller, interacting entities (for example, they can re-create a virtual replica of the global trades by the interaction over time of digital consumers and producers in the virtual environment), adding more variables does not necessarily increase the goodness of the morel results, but it might increase the discrepancy in terms of behavior and performance between the real-world entity and the virtual model. In facts, as each variable implemented into the digital twin is affected by certain error margin, adding more and more variables imply increasing the error quantity. As such errors interact with each other in the model, they lead to more volatile and randomic results, which might be therefore more positive or negative, where positive and negative is defined by the correlation of each variable error as a result of random number operations.

Moreover, as already stated for the predictive digital twin, more variables heighten the complexity of the model, the potential for mistakes and the interpretability of the outputs, leading to distrust the digital twin.

To manage this complexity, the level of abstraction in a digital twin must align with the scale of the entity being modeled. For example, in a complex end-to-end supply chain model, simulating every single machine or operator within each facility may be unnecessary and could even distort the overall results. Instead, focusing on higher-level abstractions, such as the distribution of a facility throughput or lead times, can provide more actionable insights without overcomplicating the model.

In contrast, in a narrowly focused digital twin, such as one that models a single process step, detailed simulations of individual machines or operators can add significant value. For instance, a digital twin of a specific welding process could help identify operational improvement opportunities such as discovering the optimal settings for machine parameters to achieve the highest quality welds, leading to immediate and tangible improvements in the manufacturing process.

However, there are sinergies between small entity and large entity digital twins. In facts, to exploit the best out of process digital twins, typically, outputs from smaller digital twins are used as inputs for broader ones, creating a layered and interconnected system of insights.

As an example, consider a digital twin of a single workstation in a manufacturing line, such as a CNC machine. The inputs might include tooling configuration, machine speed, and material type. The output could be an optimized cycle time or a reduction in tool wear. This twin might also predict how adjustments to tooling disposition can shave seconds off the cycle time.

A digital twin of an entire process step or manufacturing line would take the optimized cycle time from the workstation twin as an input. Other inputs could include machine availability, labor schedules, and material flow. The output might be the overall efficiency of the process step or line, identifying bottlenecks and suggesting adjustments to maximize throughput.

Scaling up further, a digital twin of an entire manufacturing site would integrate inputs from various process steps and production lines. It might also consider factors like energy consumption, logistics, and workforce distribution. The outputs would be high-level insights, such as the optimal configuration of the entire facility, strategies for reducing downtime across multiple lines, or comprehensive energy-saving recommendations.

Conclusion

As we discussed, in digital twin technologies, the size of the replicated entity plays a crucial role in determining the inputs required and the outputs generated. Smaller entities yield specific, detailed insights, which can be fed into larger digital twins that provide broader, system-wide recommendations. This interconnectedness is especially prominent in process digital twins, where optimizing one part of the system can have cascading benefits across the entire process or even the entire manufacturing site. Understanding this relationship is key to leveraging digital twins effectively, ensuring that data flows smoothly from one level to the next, and that insights are accurately applied to improve overall operations.

Ultimately, the key to a successful digital twin lies in finding the right balance between detail and abstraction, ensuring that the model is complex enough to provide valuable insights but not so complicated that it becomes unwieldy or prone to errors. This balance is particularly important in larger-scale predictive and simulative digital twins, where the potential benefits of simulation and optimization must be weighed against the risks of increasing complexity.

Finally, in prescriptive digital twins, due to their extreme complexity and as it usually rely on a mix of predictive and simulative technologies, there is an even stronger need to achieve such balance. Therefore, in prescriptive digital twins, software developers and businesses really need to strike the best balance between level of detail and complexity, to make sure that the optimization of the virtual model correspond to the optimization of the physical entity in the real world.

01

DIGITAL TWIN TYPES AND CHARACTERISTICS

In-Depth exploration of Digital Twin Types: characteristics, technologies, and value added by area of application

02

DIGITAL TWIN ABSTRACTION LEVEL

Understand what is the abstraction level – from broad E2E digital twins to detailed object level digital twin – inputs, outputs and key questions answered

03

dIGITAL TWIN AND SYSTEM INTEGRATION

From standalone simulations to closed-loop interaction with corporate IT systems: pros, cons and challanges from proof of concept to enterprise scalability

04

dIGITAL TWIN STANDARDS

Standard vs. Custom Digital Twins: Navigating Complexity in Modern Systems