Unlocking the Power of Digital Twins: A Comprehensive Guide to Types, Applications, and Technologies

The vast Digital Twin realm

Digital twins are at the forefront of the digital transformation revolution, providing unparalleled insights and control over various systems and processes across industries. By creating a digital counterpart to physical assets, processes, or environments, organizations can simulate, monitor, predict, and optimize operations with greater precision and efficiency.

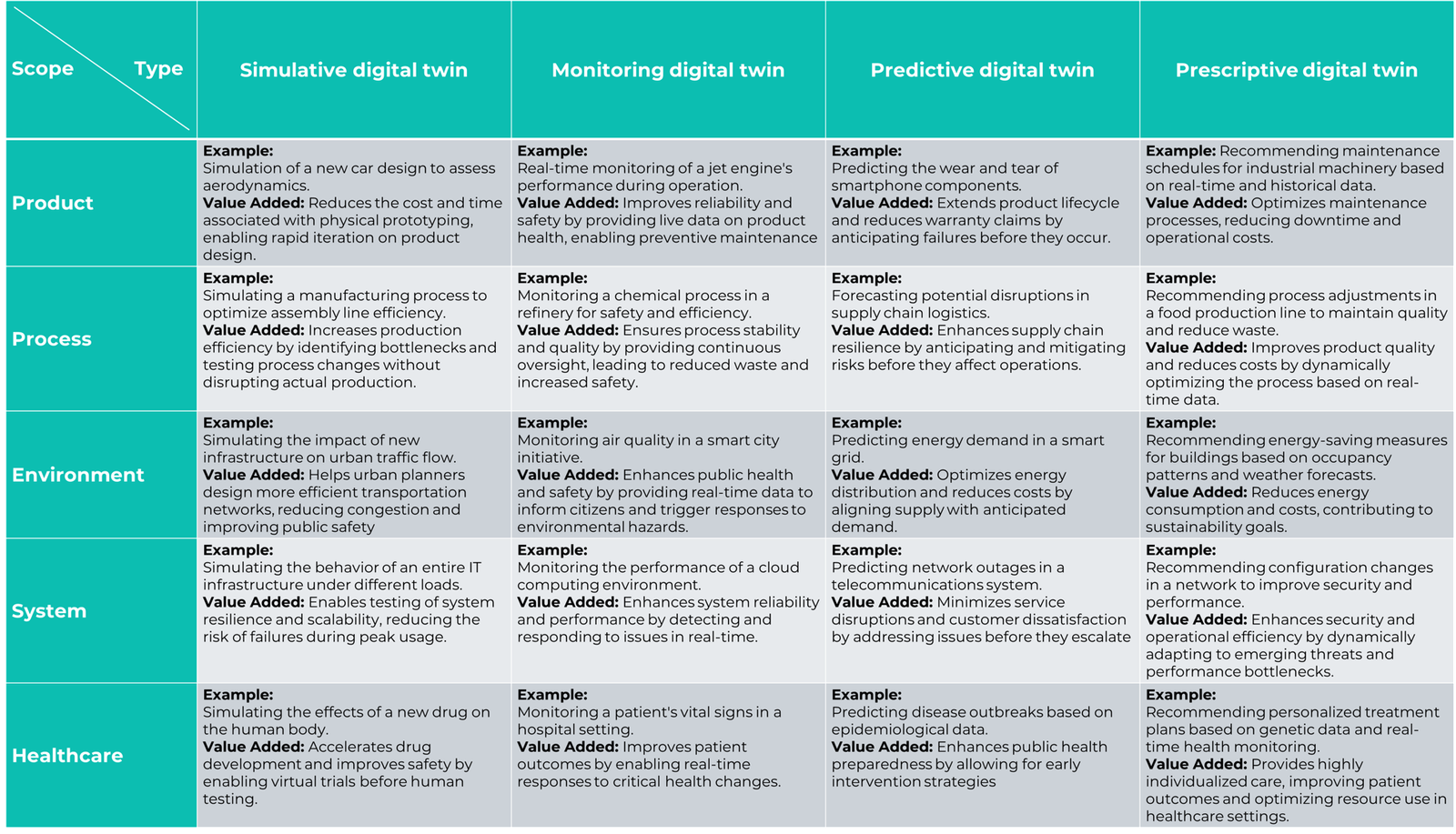

This article will explore the different types of digital twins, their applications across various domains, the value they bring, and the technologies that make them possible. A matrix, given by all the possible combination of scope and type of digital twin, filled of example and the corresponding technology stack, will serve as guide to better understand the vast realm of digital twins and give it proper dimensions and clustering. Before delving into the matrix itself, let’s first introduce the two dimensions: scope and type.

Understanding the scope of Digital Twins

Digital twins can be applied to different scopes, from addressing individual products and processes to entire environments and systems. For your convenience, we grouped them into 5 clusters, based on their physical entity they replicate.

Tap the elements to see their definition.

PRODUCT DIGITAL TWINS

PRODUCT DIGITAL TWINS

Focused on individual products or components, these digital twins enable detailed simulations, monitoring, and optimization at the product level. They are critical in industries like automotive, aerospace, and consumer electronics.

PROCESS DIGITAL TWINS

PROCESS DIGITAL TWINS

These digital twins represent entire processes, such as a process step, a manufacturing line, a logistic movement, or a supply chain. They allow for the optimization of workflows, ensuring that processes run efficiently and safely.

ENVIRONMENTAL DIGITAL TWINS

ENVIRONMENTAL DIGITAL TWINS

Covering both smaller and larger systems like a single building, smart cities or natural environments, these digital twins help in planning, monitoring, and optimizing complex systems that impact entire communities or ecosystems.

SYSTEM DIGITAL TWINS

SYSTEM DIGITAL TWINS

These encompass larger, interconnected systems like IT networks, macroeconomic interactions or entire supply chain networks, enabling holistic monitoring and optimization across multiple components and processes.

HEALTHCARE DIGITAL TWINS

HEALTHCARE DIGITAL TWINS

Applied in healthcare and personalized medicine, these digital twins focus on individual patients or human systems, providing insights into health management and medical interventions.

PRODUCT DIGITAL TWINS

PRODUCT DIGITAL TWINS

Focused on individual products or components, these digital twins enable detailed simulations, monitoring, and optimization at the product level. They are critical in industries like automotive, aerospace, and consumer electronics.

PROCESS DIGITAL TWINS

PROCESS DIGITAL TWINS

These digital twins represent entire processes, such as a process step, a manufacturing line, a logistic movement, or a supply chain. They allow for the optimization of workflows, ensuring that processes run efficiently and safely.

ENVIRONMENTAL DIGITAL TWINS

ENVIRONMENTAL DIGITAL TWINS

Covering both smaller and larger systems like a single building, smart cities or natural environments, these digital twins help in planning, monitoring, and optimizing complex systems that impact entire communities or ecosystems.

SYSTEM DIGITAL TWINS

SYSTEM DIGITAL TWINS

These encompass larger, interconnected systems like IT networks, macroeconomic interactions or entire supply chain networks, enabling holistic monitoring and optimization across multiple components and processes.

HEALTHCARE DIGITAL TWINS

HEALTHCARE DIGITAL TWINS

Applied in healthcare and personalized medicine, these digital twins focus on individual patients or human systems, providing insights into health management and medical interventions.

Types of Digital Twins

Digital twins can be broadly categorized into four types based on their primary function: simulative, monitoring, predictive, and prescriptive. Each type plays a unique role in optimizing operations and adding value across various scopes.

Simulative Digital Twins

- Application: Simulative digital twins are essential for testing and validating designs and processes before they are physically implemented. For example, in product development, simulative digital twins are used to test the aerodynamics of a new car design.

- Value Added: By enabling virtual testing, simulative digital twins reduce the need for costly physical prototypes and accelerate the design and development process. They help engineers identify potential issues early, leading to better-designed products and processes.

Monitoring Digital Twins

- Application: Monitoring digital twins provide real-time insights into the status and performance of physical assets or processes. For instance, in aviation, monitoring digital twins track the performance of jet engines to ensure they operate safely and efficiently.

- Value Added: Continuous monitoring helps detect anomalies early, preventing failures and extending the lifespan of assets. In industrial settings, monitoring digital twins ensure that processes remain within optimal parameters, improving reliability and safety.

Predictive Digital Twins

- Application: Predictive digital twins analyze historical and real-time data to forecast future states and outcomes. In supply chain management, for example, predictive digital twins can forecast future performances and potential disruptions, allowing companies to proactively address issues.

- Value Added: By anticipating future conditions, predictive digital twins enable organizations to take preemptive actions, reducing downtime, avoiding costly failures, and improving overall efficiency.

Prescriptive Digital Twins

- Application: Prescriptive digital twins go beyond prediction by recommending specific actions based on optimized agents. For example, in manufacturing, a prescriptive digital twin might suggest optimal maintenance schedules to prevent machinery breakdowns.

- Value Added: These digital twins not only predict outcomes but also provide actionable insights that optimize operations, reduce costs, and enhance decision-making processes.

The Scope/Type matrix

Given the two dimensions of types and scopes of digital twin, we can now enable detailed examples clustering to properly size the boundaries of the digital twin realm and appreciate its outstanding contribution in many different fields and ways.

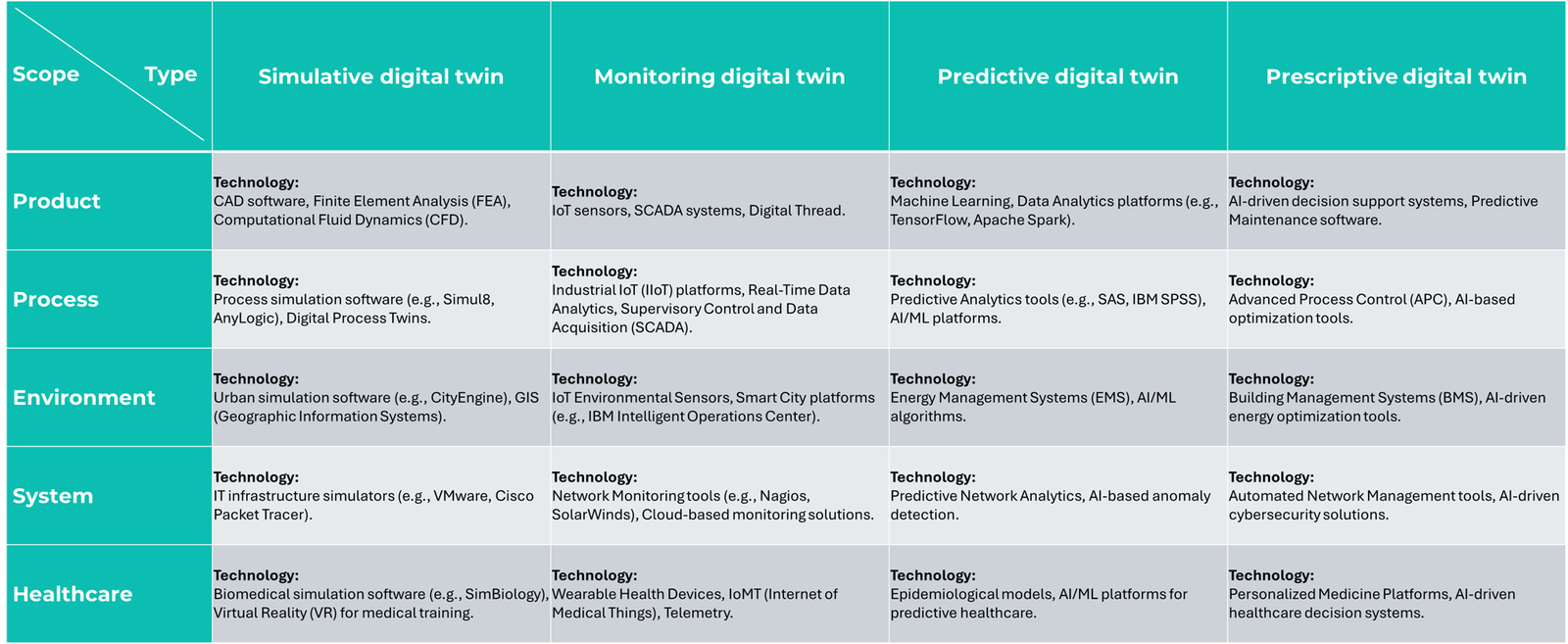

Key Technologies behind Digital Twins

Digital twins are powered by a range of advanced technologies that enable their creation, operation, and interaction with physical systems. The specific technology stack varies depending on the type and scope of the digital twin, but it can generally consists of:

- CAD Software: Used in simulative digital twins to create detailed digital models of physical objects, and in monitoring for layout rendering purpose.

- IoT Sensors: Critical for monitoring digital twins, these sensors provide real-time data from the physical entity to the digital twin.

- Simulation software: Allow to test different potential scenarios to take optimal decisions in a risk-free ambient, and constitute the perfect learning environment for optimization agents for prescriptive digital twins.

- Predictive analytics tools, Machine Learning and AI: Central to predictive and prescriptive digital twins, these technologies analyze data to make predictions and recommend actions.

- SCADA Systems: Used in industrial settings to monitor and control processes, feeding data into monitoring digital twins.

- Advanced Process Control (APC): In process-level digital twins, APC systems optimize operations by making real-time adjustments based on data from the digital twin.

The future of Digital Twins, at a glance

As digital twin technology continues to evolve, its applications will expand, becoming even more integral to industries such as manufacturing, healthcare, urban planning, and beyond. The integration of AI, machine learning, and real-time data analytics will enhance the capabilities of digital twins, making them more predictive, prescriptive, and ultimately, more valuable.

As no standard Digital twin exist – meaning there are multiple rich opportunities to leverage such solution in many ways – by understanding the different types of digital twins, their applications, the value they add, and the technologies that drive them, organizations can better harness this powerful tools to optimize their operations, reduce costs, and drive innovation. Whether you’re looking to improve product design, streamline manufacturing processes, manage complex systems, or enhance healthcare outcomes, digital twins offer a pathway to a smarter, more efficient future.

01

DIGITAL TWIN TYPES AND CHARACTERISTICS

In-Depth exploration of Digital Twin Types: characteristics, technologies, and value added by area of application

02

DIGITAL TWIN ABSTRACTION LEVEL

Understand what is the abstraction level – from broad E2E digital twins to detailed object level digital twin – inputs, outputs and key questions answered

03

dIGITAL TWIN AND SYSTEM INTEGRATION

From standalone simulations to closed-loop interaction with corporate IT systems: pros, cons and challenges from proof of concept to enterprise scalability

04

dIGITAL TWIN STANDARDS

Standard vs. Custom Digital Twins: Navigating Complexity in Modern Systems