Master the supply chain basics

Navigating Uncertainty safely

Introduction to Supply Chain Management: An overview of what supply chain management entails, including its importance, key concepts, and objectives.

Supply Chain Components: Exploring the various components of a supply chain, such as suppliers, manufacturers, distributors, retailers, and customers.

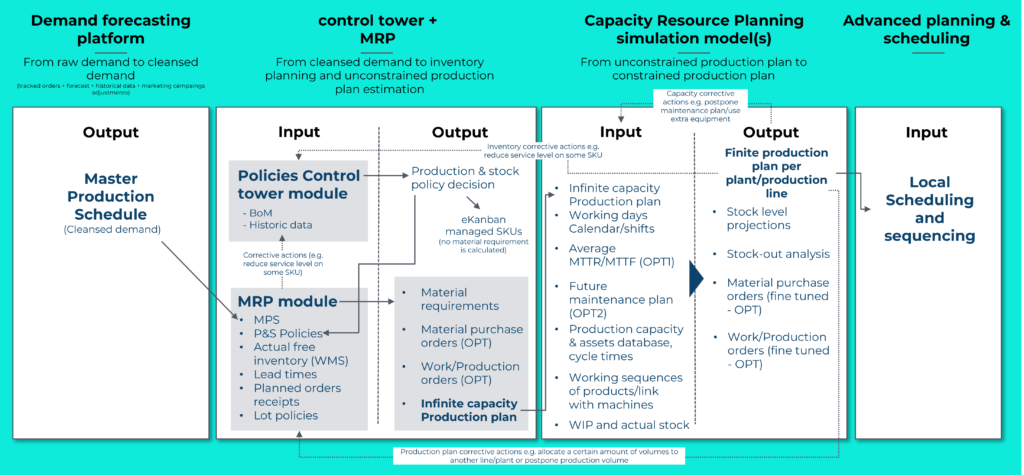

Supply Chain Planning: Discussing the process of supply chain planning, including demand forecasting, inventory management, and production scheduling.

Procurement and Sourcing: Explaining the procurement process, strategic sourcing, supplier selection, and vendor management.

Inventory Management: Covering inventory control methods, safety stock, just-in-time (JIT) inventory, and inventory optimization techniques.

Transportation and Logistics: Detailing transportation modes, logistics management, freight forwarding, warehousing, and distribution.

Supply Chain Technologies: Introducing technologies like RFID, GPS tracking, blockchain, and supply chain management software, and their role in optimizing supply chain operations.

Risk Management in the Supply Chain: Discussing risk identification, assessment, mitigation strategies, and contingency planning to manage risks effectively.

Supply Chain Sustainability: Exploring sustainable practices in the supply chain, including ethical sourcing, reducing carbon footprint, and waste management.

Supply Chain Performance Measurement: Covering key performance indicators (KPIs) for evaluating supply chain performance, such as on-time delivery, inventory turnover, and cost-to-serve.

Global Supply Chain Management: Addressing challenges and opportunities in managing global supply chains, including cultural differences, trade regulations, and geopolitical risks.

Supply Chain Resilience: Exploring strategies for building resilience in the supply chain to withstand disruptions such as natural disasters, supplier bankruptcies, or geopolitical conflicts.

01

Simulation modelling for disruption analysis and mitigation action testing

Learn how simulation modelling can support deeper understanding of disruptions and enable your business to test mitigation actions in a risk-free environment

02

Monitoring risks via probabilistic modelling and bayesian networks

Discover how to continuously monitor the risk profile thanks to an Enterprise Risk Management tool based on Bayesian Networks, Direct Acyclic Graphs and conditional probabilities

03

Monte carlo method to discover all about risks based on their severity

Estimate the potential effect of the power of chaos and randomicity on your supply chain. Empower any static risk analysis with steroids thanks to Monte carlo method